Meet the future: green steel

Green steel can play an important role in the global sustainability process, but it is still a relatively unknown and untapped phenomenon. In this article, we answer some questions so you can get a better idea of green steel.

What is happening within the steel industry to become more sustainable?

The European Commission has imposed a levy system: CO2 polluters will pay extra taxes. If factories generate fewer emissions, they pay less taxes. This obviously plays a big role within our industry as well.

You see now that all reputable steel mills are working on sustainability. European mills are each trying in their own way to reduce CO2 emissions, and green steel can contribute substantially to improvement.

What is green steel?

There is no definition for green steel. Logically, however, it does require that CO2 emissions from the production of green steel be reduced compared to the production of gray steel. There are currently two common ways to produce green steel.

1. Invest in new techniques and ideas around plants and production process that lead to CO2 reduction. For that result, the steel mill can receive certification. If, after research, it is concluded that CO2 emissions are reduced by, say, 20%, the factory gets a certification. The factory can then say that 1/5 part of its steel is green steel. But you don't know what part and all the steel is sold claiming a 20% reduction in CO2 emissions.

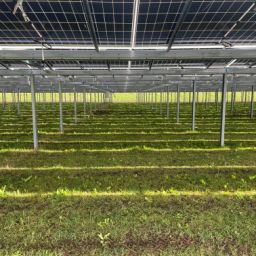

2. Another route toward green steel is the use of scrap metal. Especially if that scrap is processed in an electric furnace that runs on green energy (windmills solar panels). In terms of production, this route is much greener than production with a regular blast furnace. Moreover, buyers know exactly what role steel is really green. In Europe, there are currently only a few electric blast furnaces. It will take years and years to seriously increase the capacity of electric blast furnaces. The U.S. already has many more electric blast furnaces.

Is green steel different from gray steel?

No, the final product green steel meets the same quality requirements and properties as gray language.

Who is green steel suitable for?

Since the quality is identical to regular steel as well as the fact that green steel is more durable, green steel is suitable for all steel processors. It is fair to say that green steel is more expensive than gray steel.

When weighing the costs, it is important what proportion of steel is in an end product. If it is a (relatively) small percentage, such as in a car, a higher price for green steel will have little impact on the final price. But if you manufacture products that consist of perhaps 90% steel, then an increase in the price of green steel is quickly responsible for a significant price increase in the final product. Each company must make its own trade-off. Companies that are leading or that consumers expect to be leading and innovative and sustainable are more likely to switch to using green steel.

We expect the application of green steel to increase rapidly under pressure from regulations, market demand and corporate social responsibility.

Interested?

Interested in the application of green steel? Please contact us.

Vul hier uw eigen inhoud in.

.jpg?width=256&format=jpeg&dpr=1.0&signature=d0c79bb2859051748b8f93bc65ffac3a5e1d1ae5)

%20-%20Z9-14-Edit%20kopie%CC%88ren.jpg?width=256&height=256&mode=crop&format=jpeg&dpr=1.0&signature=21a563ec612ffcd7e853e57c02369a69e8dfb0cf)