What we do with 3D printing

KS Systems is always working on the best solutions. That's in our DNA, but not everything we do to create the best possible products is immediately noticeable. For example, we use 3D printing to deliver our projects in the best possible way. R&D engineer Dominique van Langeveld of KS Systems tells more about its application.

Striving to work flawlessly

"Quality for customers is always paramount. Within our organization, products go through many stages before the final product is delivered to the customer. We strive day in and day out to work flawlessly and then it is important to maintain as much control as possible. We do that, for example, by making 3D models to ensure optimal production."

Getting the right products on time

"We make complex products, and manufacturing them can also be complex, as different variants are often produced, sometimes with minor differences. To give the production department clarity about the products to be manufactured, we use 3D printing to create models," Dominique said. "With a model and a technical 2D drawing, we give our colleagues on the production line optimal information so that errors are avoided. As a result, we deliver the right products to our customers on time, we do not waste material and there is no additional pressure on production capacity."

More applications

"Our engineers also use 3D printing in the development phase to create test products. It is ideal to print test products quickly and affordably before making a steel version. Models are also used on the production line. If we print an outside contour that can be used in the production of an emulsion plug of a high-frequency line, the production department does not have to mill or order such a contour. So that saves time and money."

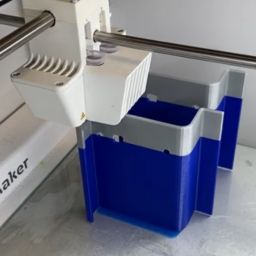

About the 3D printer

KS Systems is a company where technology and innovations are important. Everyone is working on it, and enthusiasm for thoughtful solutions can be high. For example, read what Dominique has to say about the 3D printer his colleagues and he are working with.

"We have an Ultimaker s5. For us the best 3D printer currently available in the market. The device is composite-ready and has double extrusion, has a print volume of 330x240x300 mm and is compatible with more than 200 materials. It also makes complex shapes accurately. Furthermore, there is the option to use less material by not printing solid. In addition, the speed is variable, which is useful when a model profile is needed at short notice."

KS Systems has extensive experience with 3D printing. Want to know what KS Systems can do for you and how we can use 3D printing to make your project effortless? Then contact Dominique van Langevelde at dominique.vanlangevelde@kssystems.com.

Vul hier uw eigen inhoud in.

.jpg?width=256&format=jpeg&dpr=1.0&signature=d0c79bb2859051748b8f93bc65ffac3a5e1d1ae5)

%20-%20Z9-14-Edit%20kopie%CC%88ren.jpg?width=256&height=256&mode=crop&format=jpeg&dpr=1.0&signature=21a563ec612ffcd7e853e57c02369a69e8dfb0cf)